IC Cleaning Model 888 Station

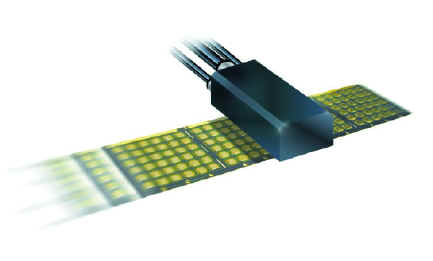

ALLTEQ's Cleaning Head is built to match the product which will be passed under it for cleaning. The Head incorporates ports for particle blow-off and vacuum suck back. Special cleaning head configurations are available for different strip, package or wafer sizes.

Retrofit to your, Die Bonder, Wire Bonder, 3rd Optical Inspection Station, Dispensing System. Flip Chip Bonder. Molding Press. Frame Loader................

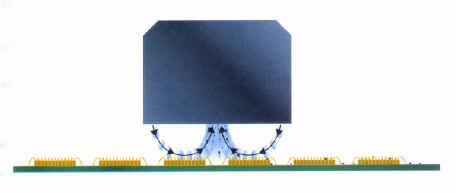

Cleans Dust , Silicon Particles, Hair, Fiber, Detached Particulates, Statically Held Particulates, Detached Bonding Wire, Lint....

Clean Cavity Packages, MEMS, Leadframes, ETC. prior to encapsulation or sealing.

FINE PRINT: The 888 will not remove any mechanically attached materials, glues. epoxies or trapped objects.

The 888 IC Yield Master consists of three components:

1. Cleaning Head for ionizer blow off and vacuum suck back

2. Ionizer Unit

3. Vacuum Box with HEPA Filter

1. The Cleaning Head

|

|

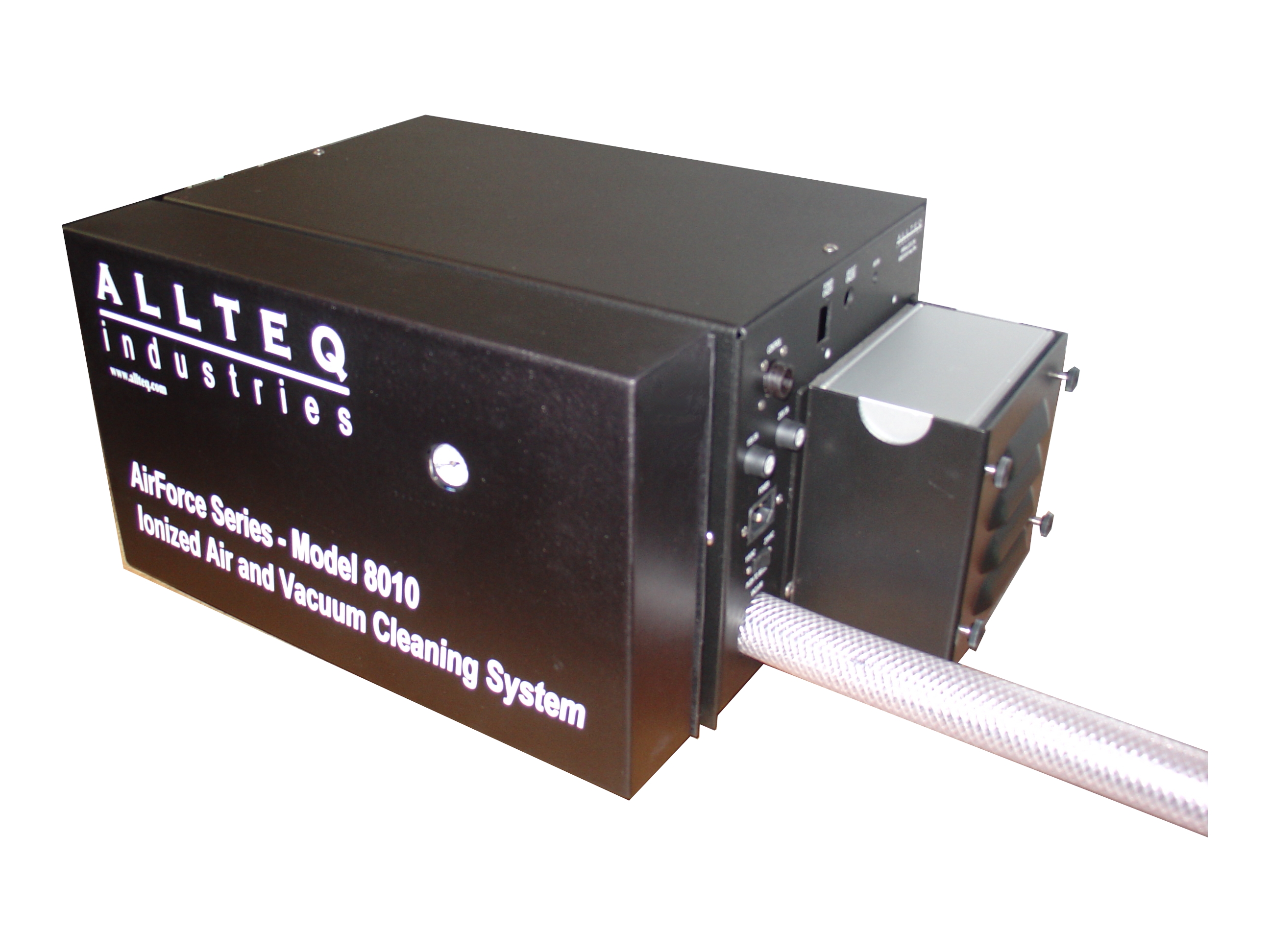

2. The Ionizer Unit Just blowing the particles off the devices is not enough ! |

|

|

|

The Ionizer When fed from an ultra-clean gas source, the ionizer of the 888 operates 10 times better then Class 1 clean room requirements. To virtually eliminate particle emissions, the design includes a tightly controlled emitter point shape, corona voltage and current. Careful material selection and control of internal geometry ensure ultra-clean ionized gas delivery. The ionizer uses a patented, intrinsically balanced technology, which ensures electrical neutrality and safe operation in the tight confines of the production equipment. It is based on extreme electrical isolation and relies on conservation of charge to achieve balance. With this technology, the 888's ionizer will never need calibration. Ionizer Features:

|

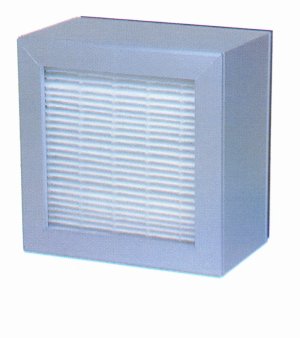

3. Vacuum Box with HEPA Filter

|

|

|

DO THE MATH: You are running 1,000,000 devices per week. Your yield is 97% +-. You are throwing away 30,000 units per week or worst yet some are sent your customers. Out of the 30,000 half are rejected because of foreign particles, The 888 can save 50% of this 15,000. That's 7,500 units per week that could be saved by the 888. 390,000 per year! Can you afford not to try the 888? |

The Vacuum Unit:

The vacuum unit of the 888 is aself-contained system, which incorporates a highly reliable, maintenance-free vauum pump. The harmful particles are drawn up into the the pump box and into a 0.3 Micron HEPA

filter before returning to the air to the room.

Vacuum Unit Features:

HEPA Filter:

|

|

Note: The 888 will not remove paticles that are mechanically connected to the leadframe/substrate or die, nor will it remove any particles that the trappd under

the wires of the wire-bonded device.

Yield Improvement:

The 888 can be retrofitted to a wide range of process equipment. The 888's technology has been field proven to increase the final yields of integrated circuits by removing harmful foreign materials from leadframe during the IC manufacturing process. We are sure you, and your customers, will have peace of mind knowing that every leadframe will be cleaned of foreign materials on each machine where a 888 is used.

Retrofit to you: Die Bonders Wire Bonders Inspection Systems Die Coating Systems Molding Equipment Leadframe or Boat Indexing Systems SPECIFICATIONS: PHYSICAL PUMP BOX

Weight:

23 lbs. CLEANING HEAD

Weight:

1 lb. Note: Special cleaning head configurations are available. INONIZER

Weight:

1.5 lbs.

Depth: 20 inches

Width:

10 inches

Height:

10 inches

Depth: 5 inches

Width:

1.5 inches

Height:

1 inches

Depth: 5.5 inches

Width:

6 inches

Height:

7.5 inches